Customized product

The range of customized products is extensive. It has a complete design process, a professional design and manufacturing team, and 20 years of experience in manufacturing optical lenses.

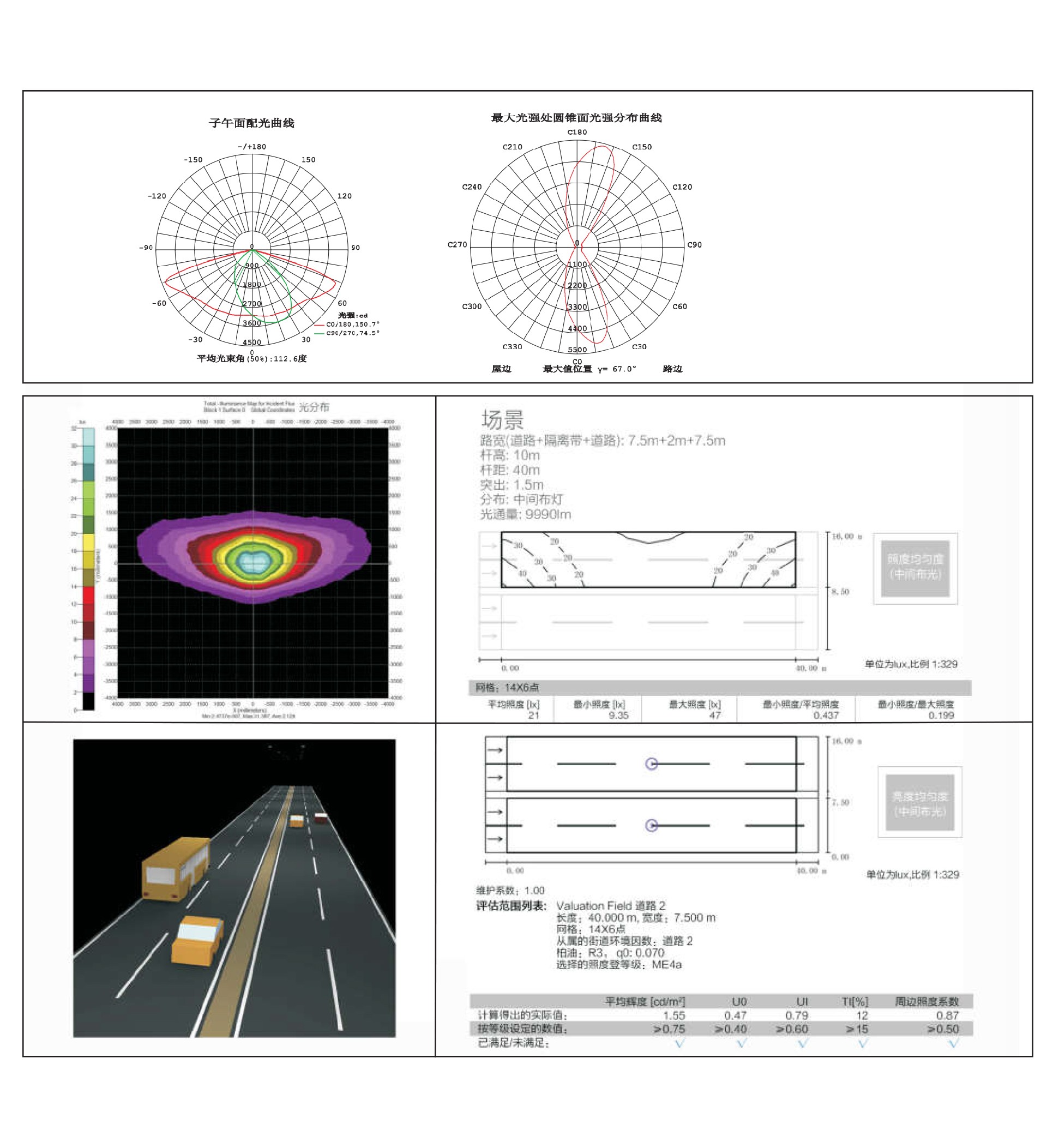

Street and industry lighting lens

The company has 4 professional optical designers with more than 7 years of working experience. They can quickly provide design solutions according to different usage scenarios and national photometric standards. The company possesses various types of high-precision mold processing equipment, which can rapidly complete mold production and timely finish injection molding to provide products to customers.

Security and traffic display lighting lens

Be able to provide quick feedback to customers' demands, meet various security optical standards, and offer better traffic display effect solutions.

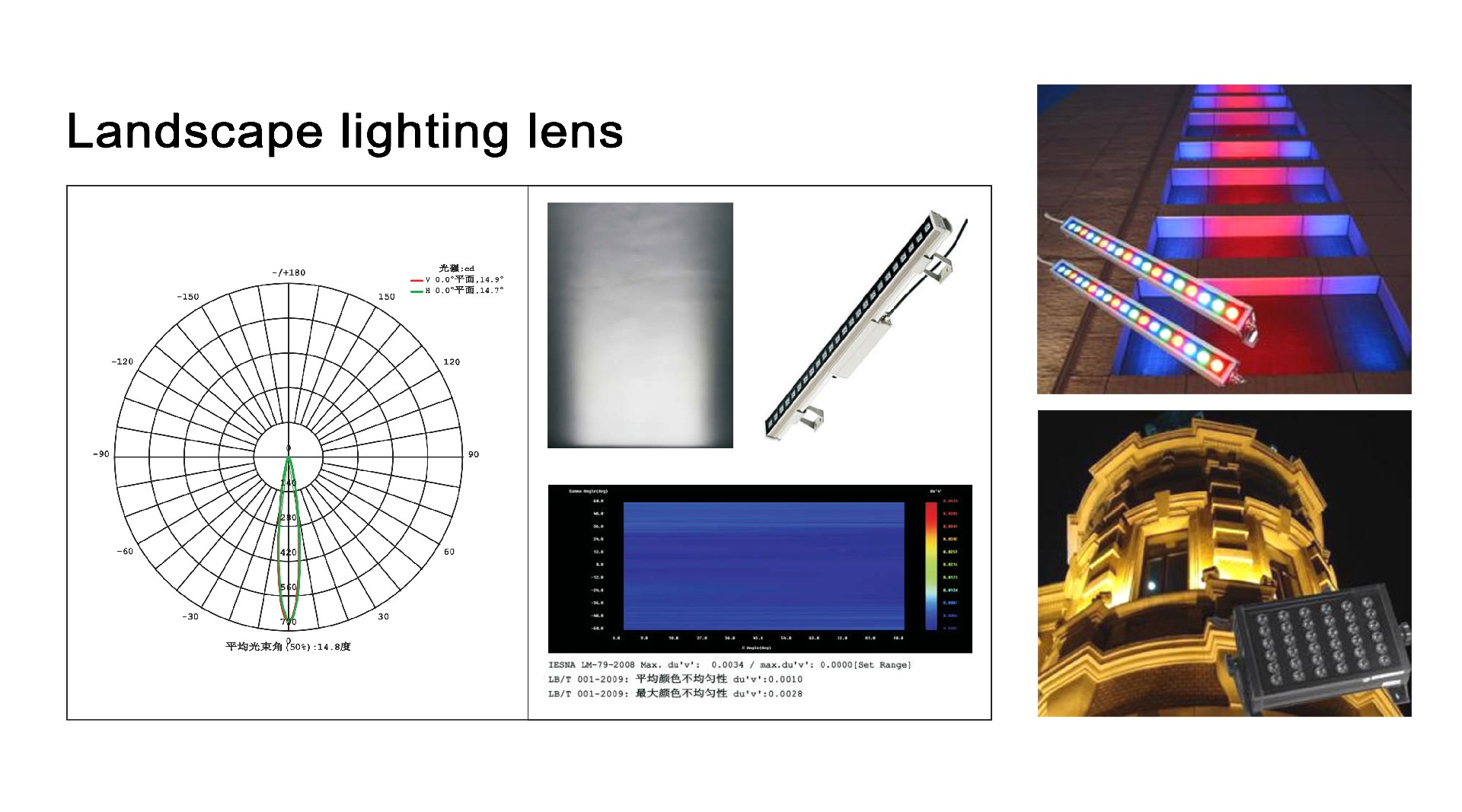

Landscape lighting lens

Six types of landscape project lenses have been successfully developed, meeting the optical requirements of various landscape projects. Various samples can be quickly provided for customers to choose.

Mobile lighting lens

We have successfully cooperated with the top 5 mobile lighting customers in China's industry to develop various lenses, with stable and large-scale shipments. We have excellent quality and rich experience, and can quickly respond to customers' customized demands.

Business lighting lens

The company has 20 years of experience in manufacturing optical lenses and maintains stable cooperative relationships with major lighting manufacturers in the industry such as NVC, CDN, FSL, and TOSPO.We have long cooperated with customers to customize all kinds of lenses, and have been widely recognized by customers in terms of optical performance, timeliness, price and cost.

Stage lighting lens

Our company has unique technical insights into the zoom and mixed light technologies of optical lenses and has accumulated 18 years of development experience, which can meet the technical requirements of various types of lamps such as spotlights, moving head lights and color wash lights.

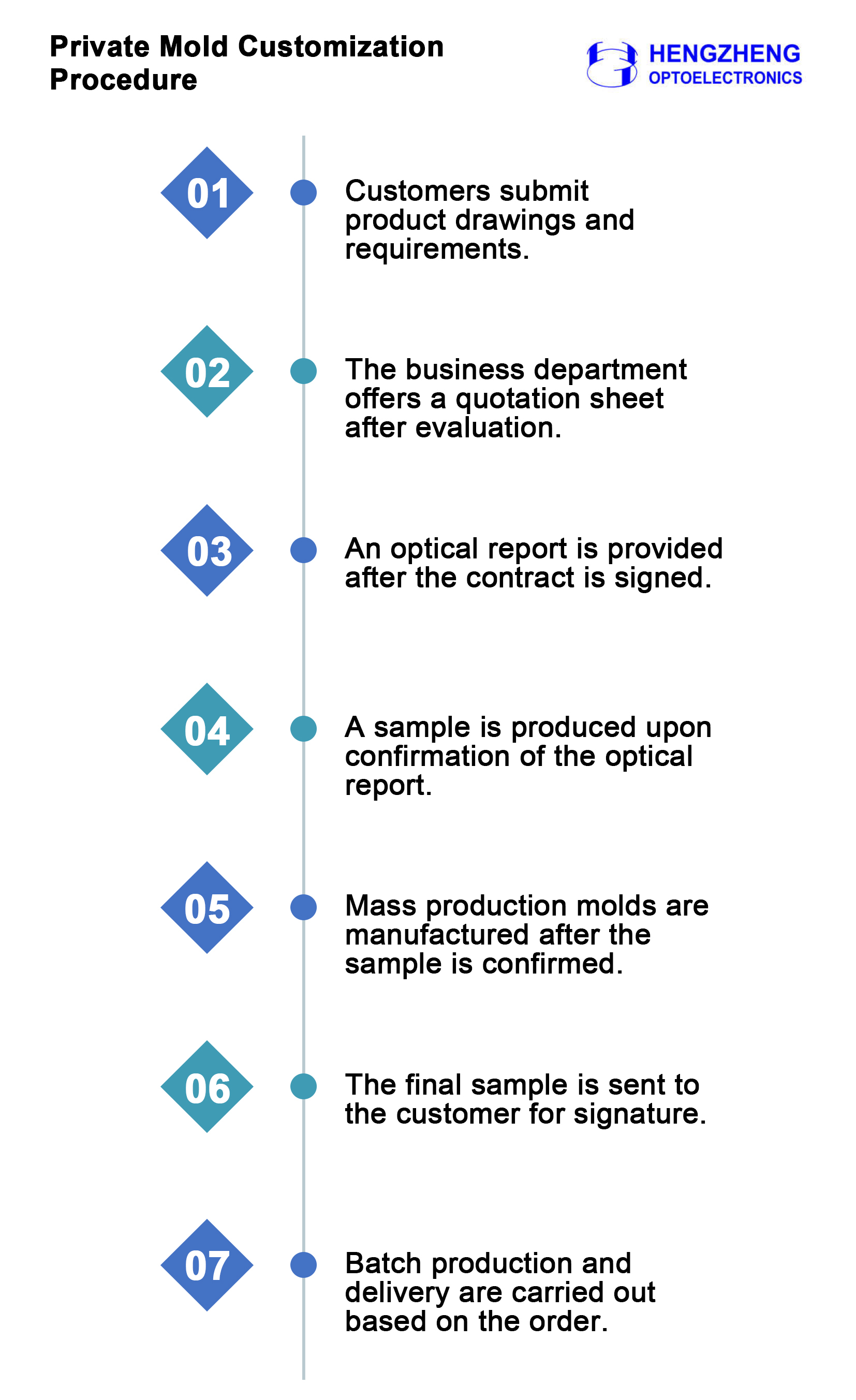

Private Mold Customization Procedure

1. Customers submit product drawings and requirements.

2. The business department offers a quotation sheet after evaluation.

3. An optical report is provided after the contract is signed.

4. A sample is produced upon confirmation of the optical report.

5. Mass production molds are manufactured after the sample is confirmed.

6. The final sample is sent to the customer for signature.

7. Batch production and delivery are carried out based on the order.

Last Article:No More

Next Article:No More